We offer an extensive array of feminine hygiene products tailored to suit every woman’s lifestyle. For those leading an active life even during menstruation, we provide menstrual pants.

✓ Complete production equipment

✓ Strict quality control system

✓ High-standard clean production workshop environment

✓ Advanced and standardized modern management practices

Production

Workshop & Laboratory

As a hygiene-focused sanitary pads manufacturer, we maintain transparent production processes and scientific management systems. Welcome to visit our state-of-the-art factory.

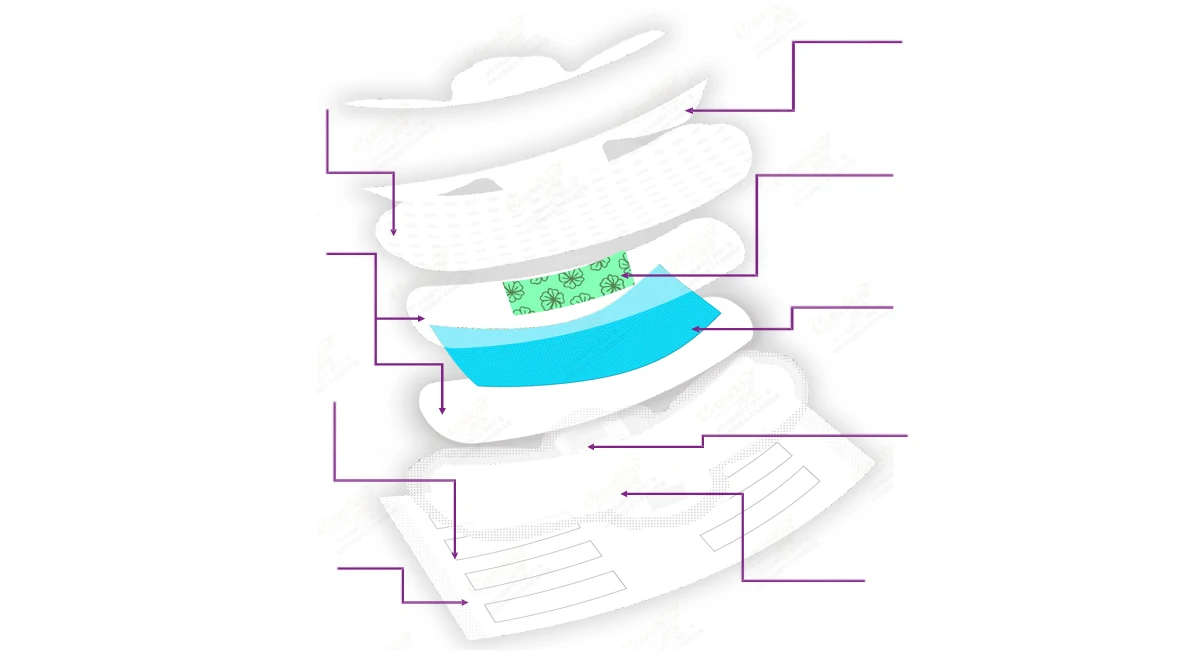

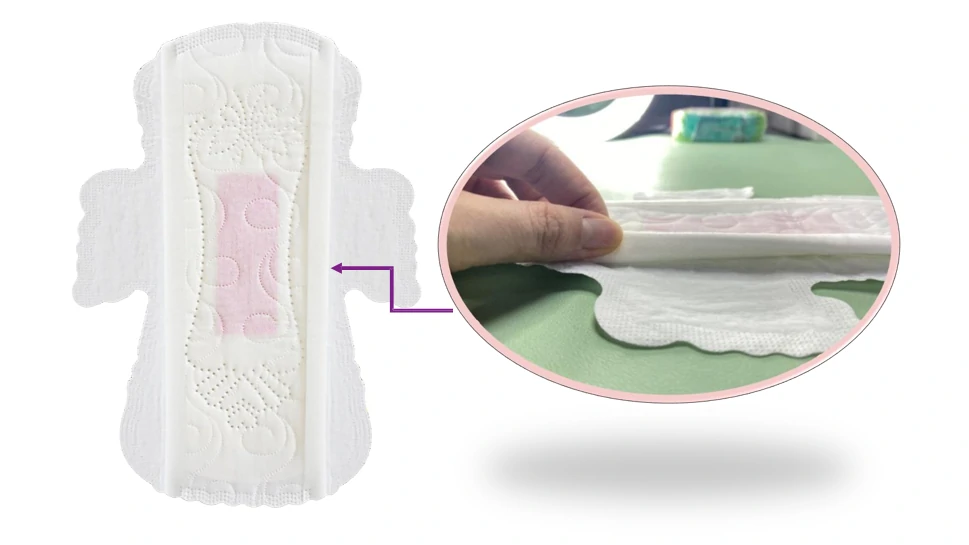

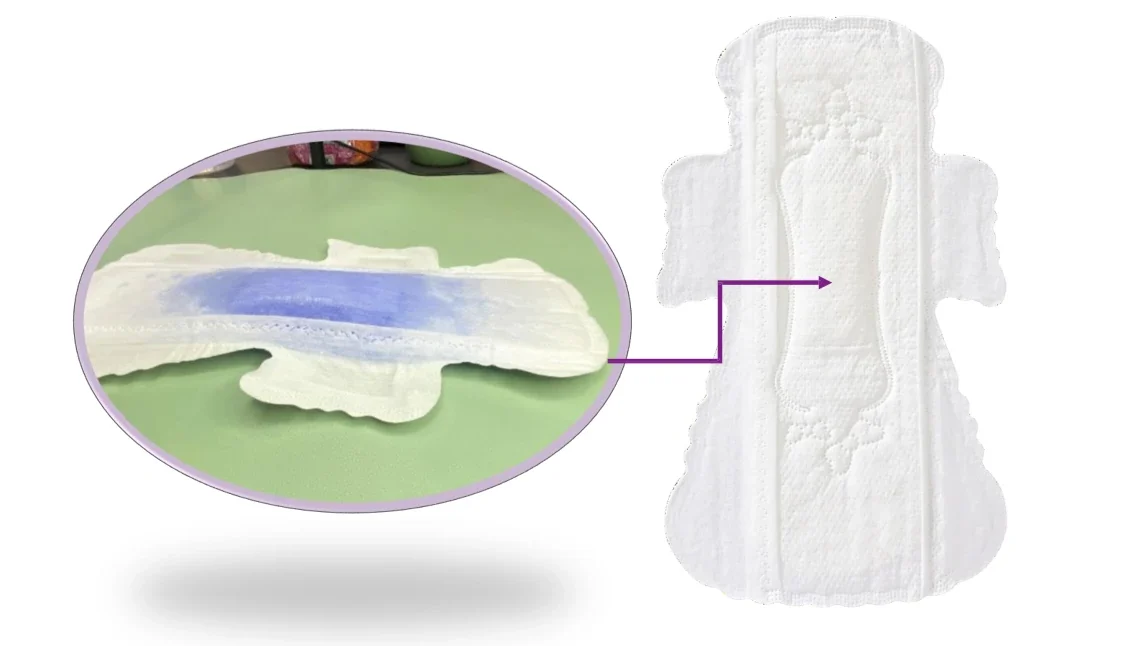

Structure of the females pads

The scientific structure and comfort of our Sanitary Napkins.

Surface layer

Air-laid paper

Adhesive

Wrapper

Three-piece anti-side leakage

Multifunction chip

Polymer composite absorbent core

Release paper

Breathable bottom film

Sanitary Napkin Production Line

Our sanitary napkin production line has ample capacity, efficiently meeting market demand.

The production line covers various types, including straight packages, quick-easy packages, and palm packages. With a complete range of product specifications—155mm, 180mm, 190mm, 245mm, 290mm, 338mm, 380mm, and 420mm in length—it can cater to the diverse needs of consumers.

The production line adopts a fully enclosed management system and is equipped with an automatic material change device.

From raw materials to finished products, the entire process is executed in one continuous formation without any manual contact, ensuring the hygiene and safety of the production process. Moreover, the line is integrated with multiple quality control systems including stain detection, metal detection, intelligent inspection, mirror inspection, and automatic waste rejection, ensuring that every sanitary napkin meets international certification standards.

The production workshop strictly adheres to hygiene management regulations.

It undergoes daily space disinfection using ultraviolet lamps and monthly microbiological sampling of equipment surfaces, material contact surfaces, and the air environment, with testing frequency exceeding 10 times. This comprehensive approach guarantees a clean production environment.

In the packaging stage, the back end of the production line is equipped with 26 fully automatic packaging machines that can achieve high-speed and stable packaging of finished products.

For customers with special customization needs, we have also set up 10 semi-automatic packaging machines to flexibly meet personalized packaging requirements. In addition, multiple coding and labeling machines are deployed to ensure that product markings are clear and standardized, further enhancing the integrity of the production process and product traceability.

Sanitary Napkin Production Line

Our sanitary napkin production line has ample capacity, efficiently meeting market demand.

The production line covers various types, including straight packages, quick-easy packages, and palm packages. With a complete range of product specifications—155mm, 180mm, 190mm, 245mm, 290mm, 338mm, 380mm, and 420mm in length—it can cater to the diverse needs of consumers.

The production line adopts a fully enclosed management system and is equipped with an automatic material change device.

From raw materials to finished products, the entire process is executed in one continuous formation without any manual contact, ensuring the hygiene and safety of the production process. Moreover, the line is integrated with multiple quality control systems including stain detection, metal detection, intelligent inspection, mirror inspection, and automatic waste rejection, ensuring that every sanitary napkin meets international certification standards.

The production workshop strictly adheres to hygiene management regulations.

It undergoes daily space disinfection using ultraviolet lamps and monthly microbiological sampling of equipment surfaces, material contact surfaces, and the air environment, with testing frequency exceeding 10 times. This comprehensive approach guarantees a clean production environment.

In the packaging stage, the back end of the production line is equipped with 26 fully automatic packaging machines that can achieve high-speed and stable packaging of finished products.

For customers with special customization needs, we have also set up 10 semi-automatic packaging machines to flexibly meet personalized packaging requirements. In addition, multiple coding and labeling machines are deployed to ensure that product markings are clear and standardized, further enhancing the integrity of the production process and product traceability.

Sanitary Napkins Manufacturing

Processes & Design

3D sanitary napkin

Raised center sanitary napkins

CONTACT INFO

0757-8665 4182

+8618928643095

No.28 Jinheng Road, Zone C, Southwest Industrial Park, Sanshui District, Foshan City, Guangdong Province, China